UK MANUFACTURED PAPER PALLETS TO SHORT LEAD TIMES

UK AND EURO SIZED PALLETS AVAILABLE

LIGHTWEIGHT FULLY SUSTAINABLE PALLETS

DESIGNED TO REDUCE THE COST OF DELIVERY and REDUCE YOUR CO2 EMISSIONS.

Decrease your shipping costs and create a more sustainable business with less impact on the environment by changing from wooden or plastic pallets to PALLITE® honeycomb paper cardboard pallets.

Calculate your annual CO2 savings by switching to PALLITE® paper pallets with our Sustainability Calculator.

RANGE OF PRODUCTS FOR LOGISTICS

Based in the UK, PALLITE® manufacture a range of lightweight, strong and recyclable products that includes pallets, layer pads and collapsible shipping crates constructed from honeycomb paper cardboard and suitable for all supply chain requirements.

Sustainable pallets offer a perfect alternative to wood that are exempt from ISPM15. No costly heat treatment or concerns over how to stop any mould growth or blue stain on the timber, PALLITE® pallets come ready to use and are 100% recyclable.

Incredibly strong pallets

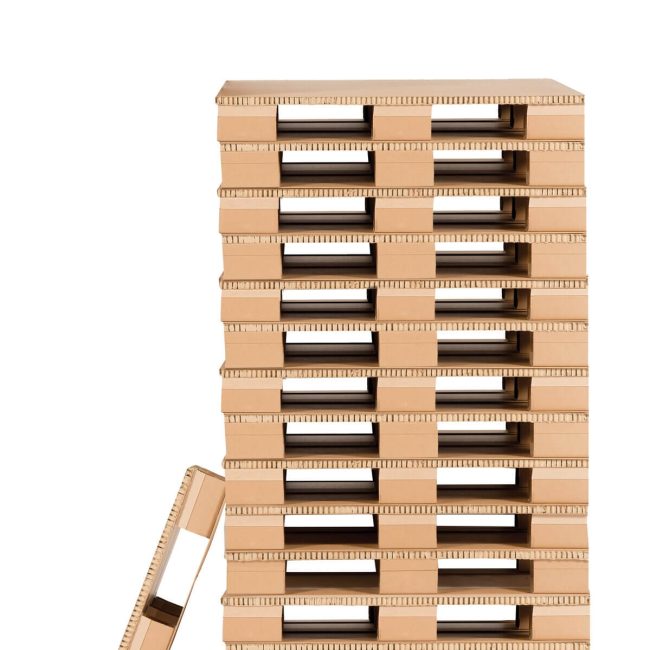

When you think of paper, durability may not be the first thing that comes to mind, but paper pallets are incredibly strong.

The unique honeycomb cell structure of the cardboard transforms this simple material into a pallet, strong enough to hold up to 750kg in open beam racking.

WE HELP COMPANIES REDUCE THEIR CO2 EMISSIONS AND REACH A MORE CIRCULAR ECONOMY.

UK and EURO PALLETS AVAILABLE

Decrease your shipping costs and create a more sustainable business with less impact on the environment by changing from wooden or plastic pallets to PALLITE® honeycomb paper cardboard pallets and shipping crates.

Contact PALLITE®

Standard Pallets

Standard Pallet

Typical use - single trip / dedicated / one-way

Can carry up to 500kg in open beam racking

Standard + Pallet

Typical use - single trip / dedicated / one-way

Can carry up to 750kg in open beam racking

Conveyor System compatible

Optional addition to have a frame long / stringer for conveyor systems.

Premium Pallets

Premium Pallet

Typical use - network / home delivery / multi-trip

Can carry up to 500kg in open beam racking

Premium + Pallet

Typical use - network / home delivery / multi-trip

Can carry up to 750kg in open beam racking

WE HELP COMPANIES MEET THEIR SUSTAINABILITY GOALS FOR THEIR SUPPLY CHAIN BY PRODUCING PALLETS, SHIPPING BOXES AND LAYER PADS THAT ARE 100% RECYCLABLE.

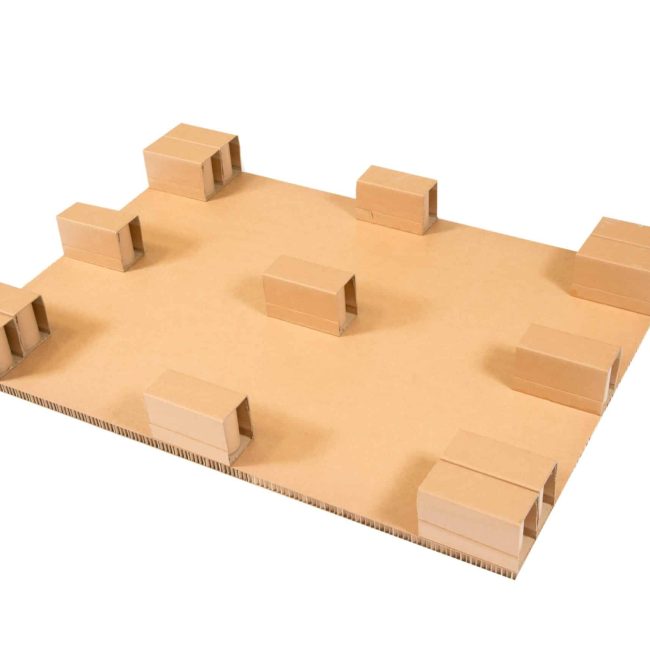

What Makes a PALLITE® Pallet?

The deck is the component of the PALLITE® pallet or pallet box that your products are loaded onto. Manufactured from honeycomb paper cells and with an outer lining with Kraft papers for maximum moisture resistance and performance, it provides a flat, slat-free surface. PALLITE® decks are just 25mm thick, with light, medium and heavy options depending on how much you need your PALLITE® pallet to hold.

The spirally wound tubes found inside the PALLITE® pallet foot add impressive vertical strength. Constructed of laminated layers of fibreboard they provide consistent performance. Our standard tubes have a vertical compression strength of 800kg per pair.

PALLITE® pallet feet are made from two laminated ‘U’ profiles glued together to encase the tubes. Bespoke sizes can be manufactured to suit customer requirements. Tubes are typically spaced every 100mm within the PALLITE® pallet foot for maximum load-carrying capability.

Base frames can be added to your PALLITE® pallet to make it suitable for conveyor systems or palletisers. These are made from flat, 90mm-wide laminated fibreboards that are added to the base of the PALLITE® pallet feet.

All PALLITE® pallet components are laminated together using PVA adhesive, familiar in most packaging sectors and widely accepted in the food and pharmaceutical sectors. Before any specification is released to the market, it undergoes extensive testing to ensure it will withstand its journey through your supply chain.

Reduce total distribution costs. PALLITE® pallets start from just over 4kg, which makes them around 20kg lighter than their wooden pallet counterparts. This means you’ll save money on fuel when travelling by road, as well on the cost of shipping and air freighting consignments, where the price may be weight dependent.

And thanks to lighter loads, you’ll also reduce the amount of potentially harmful emissions produced by transporting your goods, helping to save the planet.

All our products are made from between 80% – 100% recycled materials from carefully managed sources.

By creating bespoke pallets and pallet boxes that precisely fit the space available you can maximise container and vehicle capacity. You could transport up to 28.5% more product, saving on the number of journeys you need to fulfil a consignment, thereby reducing your carbon footprint and contributing towards your company’s sustainability goals.

We have an in-house team of designers and engineers who can provide a tailor-made logistics solution specific to your company and your supply chain needs. Bespoke doesn’t mean the cost will automatically increase, talk to us about your requirements, you may be surprised by the options and cost savings available whilst at the same time helping save the planet.

Switching from wooden pallets to PALLITE® paper pallets eliminates the need for heat treatment when exporting and removes the risk of contamination. A cheaper and fully sustainable option for export.

Protect your team from manual handling injuries due to the light weight of the pallets and eliminate the risk of cuts and scratches with no nails. An overall cleaner option that wooden crates.

Paper pallets are commonly designed for one trip and often for export outside the UK. They can be easily recycled after use, minimising the need for return flow of empty wooden pallets which could provide thousands in potential savings in addition to the huge benefits towards CO2 emissions. That said, they are durable and if properly handled they can also be used time and time again in a closed loop system.

Replacing wooden or plastic pallets with lighter materials creates positive effects on fuel costs and the impact on density for storage in warehouses.

This transition to sustainable paper pallets makes it possible to increase filling rate (more products in each transport shipment) at the same time as securing tangible environmental benefits.

If every business that used wooden pallets in a year switched to PALLITE® pallets, more than 600,000 trees would be saved – representing an area the equivalent to 6,828 football pitches, or 17 times the size of the city of London!

‘Being a leading pharmaceutical company, we needed a pallet that would help us remove nails and splinters from our supply chain… a pallet that we could send our product overseas on and a pallet that saved us weight when we airfreighted.

PALLITE® continues to deliver on all fronts.’

NAPP