In a world where environmental consciousness and corporate responsibility are playing an increasingly important role, the choice of shipping materials has become a pivotal concern. By using sustainable shipping crates companies can not only become more efficient and competitive, but lead the way in terms of their eco-friendliness.

In this article we’ll examine the many advantages of adopting environmental packaging, as opposed to using conventional wooden or plastic alternatives.

In particular we’ll see how switching to PALLITE® shipping crates can rapidly transition your organisation into becoming more sustainable, whilst simultaneously making improvements to your distribution network.

Green shipping: Reducing CO2 emissions and promoting sustainability

Wooden pallets contribute to overflowing landfill sites, and perpetuate a wasteful linear supply chain model, in which items are eventually discarded. When wood breaks down it releases methane, a greenhouse gas with a global warming potential that’s 28 times that of carbon dioxide.

This means wood is probably not the best pallet material to opt for, if you’re looking to build a sustainable, circular, business model.

Plastic pallets, although they have a longer lifespan than wooden pallets, often eventually end up in landfill too, where they can take hundreds of years to decompose, while releasing harmful chemicals into the atmosphere.

In comparison, PALLITE®’s sustainable shipping crates are made from ethically sourced materials, and they’re manufactured using clean technology. Since they’re made from paper, they’re also fully recyclable at the end of their life, reducing the contribution to solid waste, and lowering carbon emissions.

Cost efficiency: Lowering expenses with sustainable shipping solutions

PALLITE® crates are incredibly lightweight, weighing in at just 12.4kg – 83% lighter than a wooden crate. This makes for lighter loads in transit, with a reduction in associated fuel costs, and a reduction in carbon emissions. Overall costs per load, and costs to get products to their final destination will fall significantly.

Being far lighter than traditional wooden crates means that PALLITE®’s sustainable shipping crates are easier to handle and transport. They’re also easy to assemble, and disassemble, minimising the time and effort required for packaging operations, adding to overall supply chain efficiency.

Compliance when shipping abroad with ISPM 15 exemption and regulatory benefits

ISPM 15 standards were introduced to control the spread of pests which affect plants and plant products. They primarily deal with the treatment of wooden packaging products, in particular pallets, which are required to undergo heat treatment (wood is heated through to the core at 56 degrees C for a minimum of thirty minutes).

This process is not only time and energy consuming, but adds an extra layer of complexity and cost to companies that rely on wood packaging. With seamless flow of goods critical for businesses to survive, this additional time will impact the bottom line.

And if wooden crates arrive in their destination countries without a certified stamp, loads can be heat treated, debarked, buried, chipped – or destroyed completely – all at the expense of the shipper.

Because PALLITE® shipping crates are made of paper, they don’t fall under ISPM 15 requirements, making them ideal for export consignments. They save you the time and effort involved with the inspection of wood pallets, and remove the burden of having to deal with heat-treating pallet paperwork.

Durability and reliability: The strength of PALLITE® Group’s sustainable shipping crates

Unlike standard cardboard pallets, PALLITE® products are incredibly durable and have a load bearing capacity of 750kg. Even when stacked, these heavy-duty pallets can hold up to 500 kg worth of products.

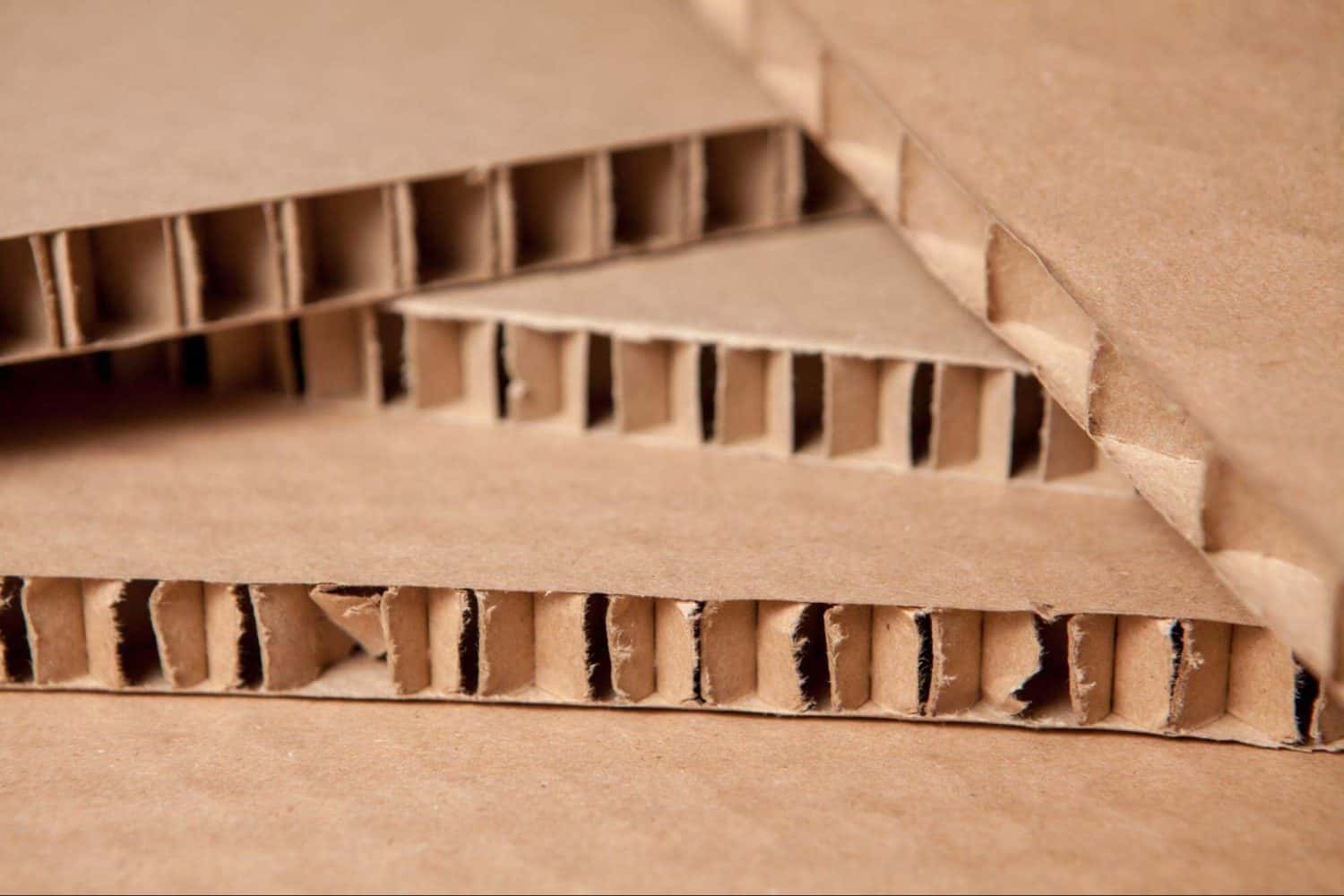

PALLITE® shipping crates have this extra durability due to their unique honeycomb patented technology, which also provides superior shock absorption and vibration-dampening properties. PALLITE® crates provide a protective barrier against impacts, ensuring that items arrive in pristine condition.

The stability of the boxes design ensures there’s reduced risk of movement during transit and therefore a reduced risk of damage to products, resulting in fewer returned products, reduced waste, and enhanced customer satisfaction.

Our nail and splinter-free shipping containers also help to reduce the risk of contamination to products in transit, as well as improve health and safety for staff who have to handle the crates.

Versatility in design: Custom boxes for diverse distribution needs

In comparison with standard wooden or plastic pallets that only come in a limited number of sizes, PALLITE® crates can be custom built depending on the exact nature of your items. We can create a cost-effective solution customised to your exact load, size and weight requirements. This enables you to fit in more units per load – thereby helping you make significant savings.

Since boxes are designed specifically to optimise space during transportation, there’s also a reduced need for additional packaging materials. You can also use PALLITE®’s bespoke inserts and sustainable void fill in your shipments, eliminating any excess space while keeping items safe and secure during transit.

The result of using PALLITE® shipping crates: A more compact, efficient supply chain, with reduced storage costs, and improved handling capabilities.

PALLITE® Group products in action: How PALLITE® created a bespoke solution for BIL

Our pallets proved a resounding success with BIL Group by helping them improve their daily processes within their Skoots Moving system.

BIL are a leading manufacturer of casters, wheels, and handling equipment, and supply their products to UK supermarkets, airports and the MOD. They’re continuously looking at ways to improve processes and standards.

BIL previously used wooden pallets which, though more environmentally friendly than plastic pallets, still fell behind what BIL wanted in a shipping product.

PALLITE® specialists designed a bespoke fully recyclable packaging solution for BIL which included base pallets with location holes, to keep the Skoots systems positioned correctly, along with a shipping crate wall, and lid, to protect goods in transit. BIL were delighted with this new bespoke professional design – and achieved their goal of contributing to a more sustainable future.

Supply Chain optimisation: Enhancing efficiency with sustainable packaging

In an era of increasing environmental consciousness, sustainable shipping crates and pallets are gaining prominence. PALLITE® products stand out, since they’re made from part recyclable materials, and are easy to recycle, reducing waste and environmental impact.

At PALLITE® Group we’re a leader in the design and manufacture of strong, clean, environmentally-friendly paper packaging solutions. Our products allow you to lower your costs, and benefit everyone along the supply chain.

By adopting PALLITE® products you can align your organisation with sustainable practices and enhance your corporate social responsibility, as well as appeal to eco-conscious customers.

PALLITE® Group works with both 3PL’s, 4PL’s and individual companies. From automotive manufacturers, to pharmaceutical companies, we help to streamline processes in the supply chain. If you’d like to find out more about how our innovative environmentally-friendly packaging solutions can help improve your distribution network, get in touch today.