The Brief

We were asked by a company that produces sensitive monitoring equipment to create a product that would ensure their equipment was delivered safely, undamaged and in fully sustainable packaging.

From our conversation with this company, we established:

• The product was highly fragile and can be damaged easily.

• It can become damaged from vibrations or if it becomes loose from the protective packaging.

• The product was being shipped using a plastic liner and expanding foam, which are not recyclable materials and often end in landfill.

Our Solution

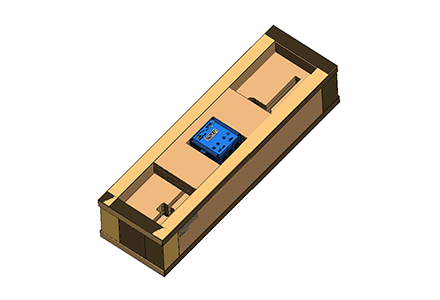

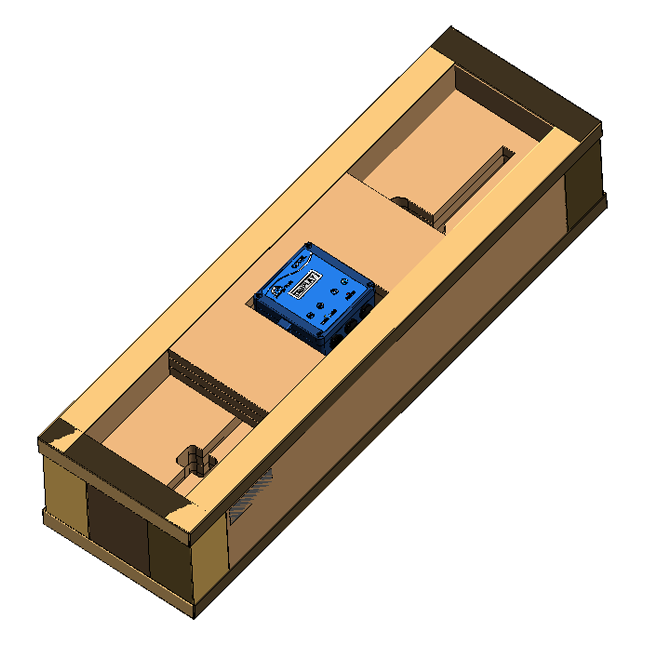

Using our PALLITE® Shipping Crates and custom inserts, we knew we could create a product that would meet all their requirements. After receiving the specifications of the product, we were able to create a design that would securely hold the product and help the customer reach their goals.

This was possible by:

• Using our CNC machine to create a custom outline that the product would slot into when being shipped.

• By combining our shipping boxes and customised inserts we can reduced the number of vibrations that the products would experience.

• All our products are fully recyclable upon delivery and remove the need for an expanding foam insert.

The Outcome

After creating our preliminary designs, we were able to create a product that reached all the customers’ requirements and has allowed them to move away from timber and non-recyclable materials.

We were able to help the customer achieve their targets of:

• Switching to a fully sustainable crate that utilises our custom CNC inserts that can be recycled at the end of its life span, removing the need to use non-recyclable expanding foam.

• By using our custom insert that has been designed around the products specification the chances of dangerous vibrations have become reduced.

• Thanks to our honeycomb cardboard the client was able to completely remove away from traditional timber products. This has also helped them save money by reducing the weight of their shipment.