Whether you call it a shipping crate, pallet box or shipping box, the outer packaging used by your company to transport their product to distributors might not be something that you give much thought to in the normal course of your business.

But paying close attention to what kind of shipping crate you use can pay dividends for a financially and environmentally conscious business.

This is because your choice of shipping crate may determine how much product you can transport at one time, how much it costs you to transport those products, the environmental impact of the journey, and the likelihood of the product inside reaching their destination undamaged.

Did you know? One of our customers saved more than £180,000 a year on its air freight bill, just by switching to PALLITE®!

Want to know more? Read on…

Shipping crates explained.

Shipping crates have been around in one form or another since the earliest days of nationwide and international trade.

Often made from wood, with the option of plastic for businesses requiring a more hygienic solution, and boxes made from strong corrugated cardboard for transporting shorter distances, they provide better protection for palletised goods in transit by enclosing those goods in an outer layer of packaging.

Popular for shipping high volume or high value goods, they may be fitted with custom inserts and packaging void fill to secure those products in transit and further protect them against becoming damaged during the journey.

Wooden shipping crates: the ISPM 15 issue

Wooden shipping crates have been incredibly popular due to their strength, relatively low cost, and the fact they can be used over and over again.

However, they are not the most sustainable shipping crate option.

Wooden shipping crates are made from virgin wood that must be heat or chemically-treated before being used in international shipping under ISPM 15 regulations. Already a costly process – the financial burden this creates for businesses is increasingly being exacerbated by the rising cost and recent limited availability of virgin wood, which means that wooden shipping crates are becoming untenable for many businesses.

Plastic shipping crates: the environmental cost

Plastic packaging’s days are numbered. In all its forms; from plastic bags and polystyrene foam to plastic pallets and shipping crates, it pollutes the environment during production and at the end of its working life, with little options for recycling and an incredibly slow rate of decomposition.

It is hardly surprising, then, that governments worldwide are legislating to ban single-use plastic packaging and encouraging businesses to design plastics out of use wherever possible.

Sustainable shipping crates: the case for paper honeycomb

The case for cheaper and more environmentally friendly shipping crates is clear. At PALLITE® Group, we believe the answer lies in paper – or at least in the honeycomb cardboard we make with it.

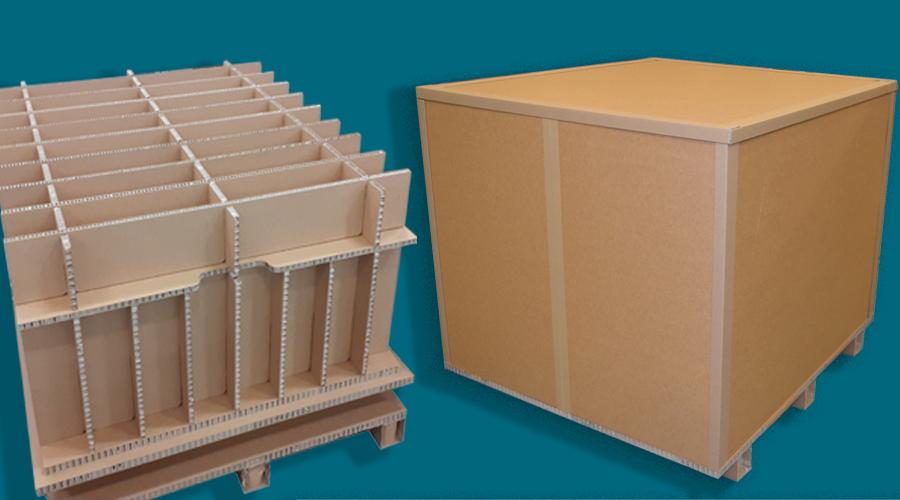

Our business centres around our innovative paper honeycomb board, developed initially for use in pallet manufacture but now used to make a wide range of sustainable products for the logistics industry, from pallets, shipping crates, layer pads and void fill, to warehouse storage solutions.

Made from layers of recycled paper sandwiched around a paper honeycomb structure and sealed with PVA glue, our paper board is lightweight, super strong, durable, clean, and incredibly versatile. It is also 100% recyclable after use.

Using this honeycomb paper board to make shipping crates results in transit packaging that doesn’t just do the job that’s required, but it also actively saves money for businesses in them meantime, whilst causing less harm to the environment.

PALLITE® shipping crates do not splinter, can hold up to 750kg and stack up to 500kg, and contain no nails. A lower moisture content than wooden shipping crates means they are also cleaner, meaning that they are less likely to grow mould.

Exempt from ISPM 15 regulations, they come with a choice of 15mm or 25mm thick protective walls and the option of adding bespoke CNC-cut inserts to hold goods in place during transportation. They can also be manufactured to bespoke sizes and can be palletised, helping businesses to maximise the use of space in lorries and containers by reducing the amount of empty space that is being shipped each time.

A standard PALLITE® shipping crate is also up to an incredible 83% lighter than a wooden shipping crate, weighing from just 12.4kg.

Shipping crate weight savings explained

Lighter weight packaging means lighter overall loads, which means lower fuel costs and fewer emissions. Meanwhile, right-sizing of loads to containers enables more products to be transported per shipment, reducing the overall number of shipments made.

Let’s look at some examples…

Example 1: Sea freight

If you substitute 30 wooden euro pallets with wooden collars and lids, each carrying a 500kg load, for the same number of equivalent PALLITE® shipping crates on board an 8,000-tonne container ship travelling the 11,907 nautical miles (22,052km) from Felixstowe dock in the UK to Shanghai in China.

The shipping company would save on fuel, and overall greenhouse gas emissions savings would equate to the charging of 63,119 smartphones.

Example 2: Air freight

If you swap 10 standard wooden pallets and crates, each holding 500kg, for 10 equivalent PALLITE® shipping crates carrying the same load, and fly them the 5,536km (3,440) miles from London Heathrow to JFK in New York.

The airline would save almost 926 litres of fuel on that journey alone, and the emissions saved would equate to charging 279,762 smartphones, or power the average UK home for 25% of the year.

To find out more about sustainable shipping crates and to discover what switching to PALLITE® could do for your business, why not give us a call?