With sustainability firmly on the global agenda, finding ways to make warehouse storage, logistics and packaging ‘greener’ and more efficient has become a priority for many businesses. One solution that can positively impact all three areas is investing in more sustainable shipping pallets, shipping crates, warehouse storage solutions, and packaging. This is where honeycomb technology comes in.

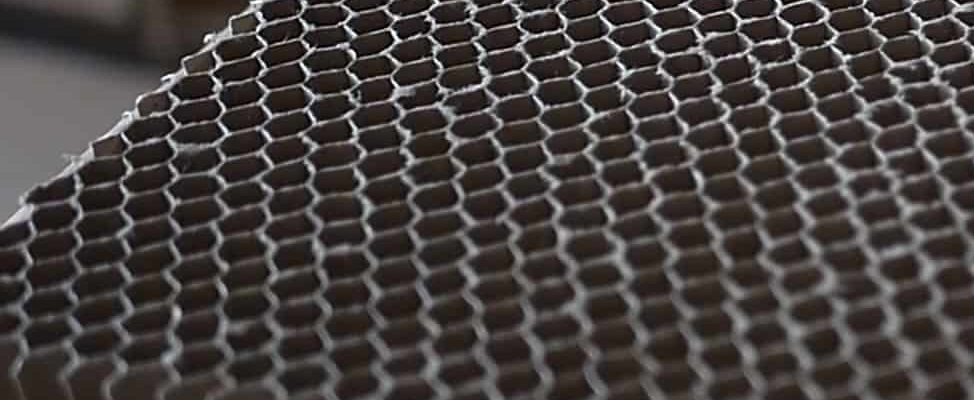

Inspired by nature, products that use honeycomb technology feature hexagonal cells that mirror those found inside beehives. This helps to create a smart material that has the ability to offer a unique combination of weight-bearing strength and easy portability due to its lightweight nature. Honeycomb materials made of paper are also typically 100% recyclable and can be used to make shipping pallets and boxes, protective packaging, warehouse storage solutions and much more.

However, how is this increasingly popular material made? Are honeycomb paper pallets, shipping crates and packaging solutions effective? And what are the advantages of this smart material? Read on to find answers to all of these questions and more.

How is honeycomb paper cardboard made?

Paper honeycomb core is made by gluing together separate bands of paper to create a collection of continuous hexagonal (honeycomb shaped) cells. These cells are then typically backed on top and bottom with flat, thicker pieces of kraft paper or card, creating a sandwich effect.

This process creates a robust structure with an impressive strength-to-weight ratio which can be explained by the I-beam principle. This is to say, while the horizontal pieces of flat outer paper act as flanges to resist bending movements, the vertically placed honeycomb structure acts to resist additional stress and provide a cushioning, shock-absorbing quality. This principle is commonly applied in large scale civil engineering projects.

What are honeycomb pallets and shipping crates?

Honeycomb paper pallets and shipping crates, such as all of those in PALLITE®’s pallet range, are a more sustainable alternative to traditional wooden or plastic pallets or crates. When compared to traditional alternatives, honeycomb products can weigh up to 85% less, meaning they are not only made from more eco-friendly and sustainable materials, they also have the potential to reduce the weight of shipments and save businesses money in the process.

As we have explained above, as well as being sustainable and lightweight, honeycomb structures also benefit from an impressive strength-to-weight ratio. This is an ideal attribute for logistics. Indeed, PALLITE®’s standard pallets, for example, are robust enough to hold up to 750kg in open beam racking.

What is honeycomb paper packaging?

As the name suggests, honeycomb paper packaging is simply packaging designed for products or large shipments that uses sustainable honeycomb structures typically made from recycled paper.

As with the other honeycomb cardboard products, packaging that makes use of this technology can offer a unique combination of strength and sustainability, whilst being extremely portable and lightweight.

An environmentally-friendly alternative to protective plastic packaging, foam inserts, bubble wrap and styrofoam peanuts, honeycomb paper packaging can provide similar levels of protection whilst reducing waste, thanks to its ability to cushion and absorb shock using only reusable and recyclable materials.

Advantages of honeycomb cell structures

Products utilising this honeycomb structure technology have a wide variety of uses in many different industries including packaging and warehouse storage bins.

Sustainability

Cardboard and paper-based honeycomb products, including shipping pallets, boxes and packaging, can be reusable and are 100% recyclable. These products are typically manufactured from a high proportion of recycled paper and only use water-based glues and adhesives.

Due to the ‘hollow’ cellular nature of the honeycomb cells, less paper is needed to produce these products when compared to traditional cardboard and corrugated paper board packaging. All of this adds up to packaging, warehouse storage and logistics products that have the potential to reduce a brand’s carbon footprint in the long term.

Strength

Due to the smart design of honeycomb cardboard structures the I-beam principle enables such products to be, pound for pound, stronger than steel.

Lightweight properties

Unlike traditional wooden, steel and plastic warehouse, logistics and packaging solutions, paper-based honeycomb structures are extremely lightweight. This can bring about savings when it comes to reduced shipping weight without compromising on the protection of the products.

Comparison with Other Materials

Honeycomb paper technology presents a unique set of characteristics when compared with traditional materials like plastic, wood, and metal. Each of these materials has distinct properties that make them suitable for various applications. However, understanding the differences in terms of strength, sustainability, cost, and recyclability is crucial for making informed choices.

Strength

- Honeycomb Paper: Known for its remarkable strength-to-weight ratio, honeycomb paper is surprisingly sturdy despite being lightweight. Its unique cellular structure, inspired by natural honeycomb, provides excellent resistance to compression and impact.

- Plastic: While certain plastics are strong and durable, they often lack the compressive strength that honeycomb paper offers. However, plastics are versatile and can be engineered for various levels of strength and flexibility.

- Wood: Traditional for its robustness and load-bearing capacity, wood is a strong material. However, its weight can be a drawback compared to the lightweight nature of honeycomb paper.

- Metal: Metals are typically the strongest and most durable of these materials. However, they are also the heaviest and often more expensive, which can impact logistics and transportation costs.

Sustainability

- Honeycomb Paper: Excelling in sustainability, honeycomb paper is often made from recycled materials and is 100% recyclable. Its production process is also less resource-intensive, making it a greener choice.

- Plastic: Sustainability is a significant issue with plastics, as they are typically derived from non-renewable petroleum resources and are not always recyclable. Their degradation can also lead to environmental pollution.

- Wood: While wood is a renewable resource, its sustainability depends on responsible forestry practices. The process of logging, transportation, and processing wood can have a considerable environmental impact.

- Metal: Metals can be recycled, but their extraction, processing, and manufacturing are energy-intensive and contribute significantly to carbon emissions.

Cost

- Honeycomb Paper: Generally cost-effective, especially considering its durability and lightweight nature, which can save on shipping and handling costs.

- Plastic: The cost of plastic varies widely based on the type and quality. Some plastics are very affordable, while others, especially those engineered for specific uses, can be expensive.

- Wood: The cost of wood can vary depending on the type and quality. Hardwoods, for example, are typically more expensive than softwoods.

- Metal: Metals are usually more expensive, both in terms of initial material costs and the costs associated with their weight in transportation.

Recyclability

- Honeycomb Paper: Highly recyclable, aligning with circular economy principles. Its ease of recycling helps reduce waste and environmental impact.

- Plastic: Some plastics are recyclable, but the recycling rates are generally low, and the process can be complex due to the variety of plastic types.

- Wood: Wood can be recycled, but the process can be challenging depending on the treatment and type of wood.

- Metal: Highly recyclable, but the recycling process can be energy-intensive.

Industry Applications

The versatility of honeycomb technology allows it to be utilised across a broad range of industries. Its unique properties make it an ideal candidate for various applications.

Automotive Industry

- Lightweight Components: Honeycomb structures are used in the manufacturing of lightweight automotive parts. This helps in reducing the overall weight of vehicles, leading to improved fuel efficiency and lower emissions.

- Impact Absorption: Due to its excellent shock absorption properties, it is used in areas that require impact resistance, such as in the construction of crash safety components.

Construction Industry

- Insulation and Soundproofing: Honeycomb technology provides excellent insulation and soundproofing solutions due to its cellular structure, making it ideal for use in walls, ceilings, and flooring.

- Structural Components: It is employed in the construction of lightweight yet strong structural elements like partition walls, roofing, and flooring systems.

Aerospace Industry

- Aircraft Components: Honeycomb structures are widely used in the aerospace industry due to their strength-to-weight ratio. They are ideal for manufacturing components like cabin dividers, flooring panels, and aerodynamic surfaces.

- Cargo Containers: Utilised in creating lightweight and strong cargo containers, facilitating efficient and safe transportation of goods.

Furniture Industry

- Lightweight Furniture: Honeycomb technology is increasingly used in the furniture industry to produce lightweight yet robust furniture, making transportation and handling easier.

- Design Flexibility: The flexibility in design offered by honeycomb structures allows for innovative and ergonomic furniture designs that are both functional and aesthetically pleasing.

If you are looking for a more sustainable and cost-effective warehouse, packaging and logistics solution for your business, contact the PALLITE® team who will be able to advise on the best option for your needs.

FAQ

What is Honeycomb in Packaging?

Honeycomb in packaging refers to a unique design inspired by the hexagonal structure found in natural beehives. This design involves creating an internal network of interconnected cells that form a honeycomb pattern. In packaging, this structure is often made using layers of paper or cardboard. The primary characteristic of honeycomb packaging is its exceptional strength-to-weight ratio, making it both lightweight and durable. This kind of packaging is used for a wide range of products, providing excellent protection while being efficient in material usage.

Is Honeycomb Packaging Eco-Friendly?

Yes, honeycomb packaging is generally considered eco-friendly. It’s predominantly made from paper, which is a renewable resource, and often includes a high proportion of recycled material. Additionally, honeycomb packaging is typically 100% recyclable, aligning well with sustainable practices. The manufacturing process of honeycomb packaging is also less resource-intensive compared to some other forms of packaging. The design’s efficiency in using materials further reduces waste, making it an environmentally responsible choice.

Is Honeycomb as Good as Bubble Wrap?

Honeycomb packaging can be as effective as bubble wrap in many applications, and it offers several advantages. While bubble wrap is excellent for cushioning and protecting items from impact, honeycomb packaging provides similar levels of protection with added structural strength. This makes honeycomb packaging suitable for heavier items that require both cushioning and support. Additionally, honeycomb packaging is more environmentally sustainable than bubble wrap, which is usually made from plastic. So, while both have their specific uses, honeycomb packaging often serves as a more eco-friendly and robust alternative.

How Do You Use Honeycomb Packing?

Using honeycomb packing effectively involves a few steps:

- Select the Right Size and Thickness: Choose honeycomb packaging material that fits the size and weight of the items you’re shipping. The thickness and cell size of the honeycomb can vary, so select one that provides adequate protection for your specific items.

- Wrap or Encase the Items: For smaller items, you can wrap them directly in honeycomb sheets, ensuring all sides are covered. For larger items, you might use honeycomb panels to create a box or encasement around the item.

- Secure the Packaging: Use adhesive tape or bands to keep the honeycomb material securely in place around the item. Ensure that the item is snugly fitted within the honeycomb structure to prevent movement during transit.

- Add Additional Cushioning if Needed: For extremely fragile items, you can combine honeycomb packaging with other materials like corrugated wraps or additional cushioning to provide extra protection.

- Label and Ship: Finally, label the package appropriately and it’s ready for shipping. Honeycomb packaging is robust enough for most transportation methods.