What makes PALLITE® different from other logistics packaging suppliers? What goes into making our sustainable packaging solutions? And what drives us as a business to keep innovating and moving forwards?

Read on to find out…

In this blog, we lift the lid on the science and technology behind our range of lightweight, super strong, sustainable packaging products. Including pallets, shipping boxes, layer pads, protective inserts, void fill and warehouse shelving units.

We also look at our history, our journey so far, and the ethos around which we are building our business.

Our products

PALLITE® Group was born out of an idea for a lighter weight, cleaner and more environmentally-friendly pallet – the paper honeycomb pallet.

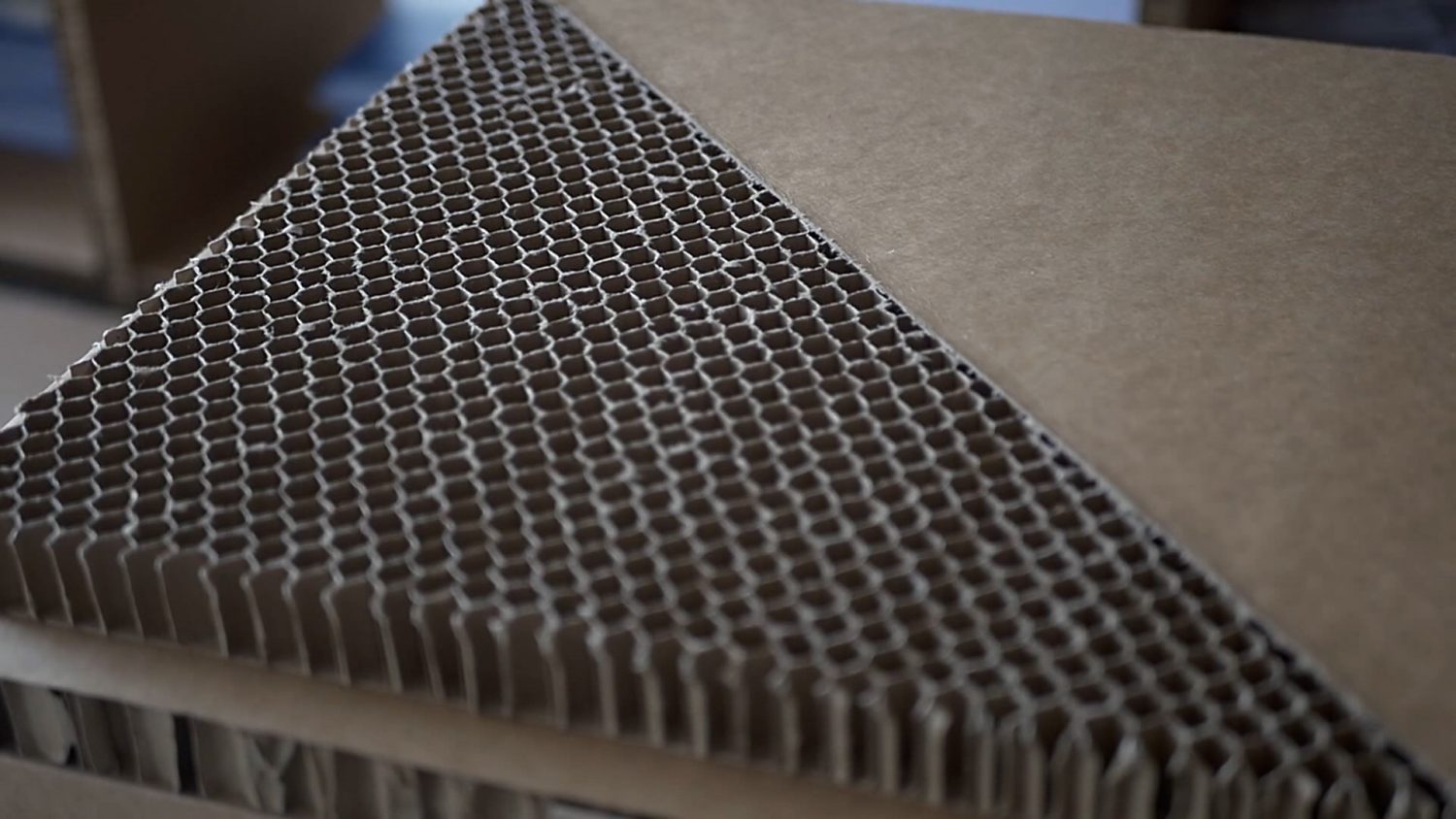

Inspired by the beauty, simplicity, and efficacy of nature’s design .We sandwiched a honeycomb structure made from recycled paper – between further layers of paper, bonded with PVA glue. Pound-for-pound stronger than steel, the resulting paper cardboard offered impressive strength, durability and usability. Which had the added benefit of being 100% recyclable after use.

The same design of board, albeit in different sizes, thicknesses and paper weights, is still used to make all our products.

Did you know?

Honeycomb structures are often found in automotive and furniture design, among other areas. Thanks to their high strength-to-weight ratio and ability to be relatively compact in comparison to other strengthening technologies.

Realising that the technology we had created could have other useful applications in logistics and warehousing that could benefit our customers. We soon expanded our product offering to encompass sustainable shipping crates, pallet bearers, layer pads and void fill inserts.

In 2019, a genuine need for better small parts storage in warehouses led to us developing our PIX® warehouse storage range of flexible pick faces – to better cater for the storage requirements of different small to medium sized, fast-moving SKUs.

Our mission

At PALLITE® Group, our mission is to provide the warehousing, logistics and distribution industries with effective solutions to their transit packaging, and storage problems, as well as forward-thinking innovations that enable competitive advantage to be gained in various areas.

For this reason, we are always innovating. Coming up with new ideas and adding new products to our ever-expanding range of sustainable paper packaging solutions.

One such innovation was the introduction of PIX® SLOTS angled.

While our PIX® and PIX® SLOTS ranges had proved popular with customers around the world. We became aware that the design of PIX® SLOTS could be further optimised for housing lightweight, slippery items such as items of apparel wrapped in plastic bags.

A small tweak to the design to angle the shelves towards the rear of the unit rather than horizontally as in the standard PIX® SLOTS unit proved sufficient to help prevent such items from falling during picking –and PIX® SLOTS angled was born.

“At PALLITE® Group, we’re problem solvers at heart. If we see or hear about a particular customer challenge, and we think our products or the paper technology we’ve developed can help. Then we’re going to do what we can to help address that challenge. PIX® SLOTS angled is a good example of this in action. It isn’t a product that will appeal to every customer, but it is one that will make a huge difference to some, and all it took was a small tweak to our PIX® SLOTS design to solve that challenge.”

PALLITE® CEO IAIN HULMES

Our values

So, if innovation and problem-solving are two of our most cherished values, what are the others?

Driven by a desire to make genuine quality products that are the best they can possibly be. We are ISO 9001 accredited in quality management and have invested extensively in developing robust manufacturing processes that ensure the consistent quality and performance of our products.

Working with some of the leading paper manufacturers in the world. We take care to select only the very best raw materials to use in the manufacturing process. Performing qualitative and quantitative quality checks on every reel of recycled paper that enters our warehouse; including checking for tears and contamination, and reviewing the paper fibre size, grammage, thickness and cobb rating.

We also believe in sustainability.

Our purpose

We exist to provide businesses with genuinely usable packaging solutions that help further their sustainability efforts.

All of our products are FSC-certified, 100% recyclable, biodegradable and designed to have a low impact on the environment during manufacture and use.

Our honeycomb paper cardboard technology is helping to eliminate potential pollutants from the environment – such as single use plastic packaging, wooden shipping crates, plastic pallets and polystyrene void fill.

The lightweight strength and space-saving properties of our transit packaging also enables businesses to reduce their carbon footprint by transporting lighter loads in fewer trips.

Our vision

Because what drives us here at PALLITE® Group HQ is a vision of a more sustainable logistics sector.

The UK transport and warehousing sector was responsible for more than 10% of the total greenhouse gases emitted by UK businesses in 2021 – equivalent to more than 45,000 tonnes.

By switching to PALLITE® products, businesses can save energy and resources, reduce emissions and support the circular economy.

“At PALLITE®, we are not just selling a commodity. We don’t see ourselves as simply manufacturers of environmentally friendly packaging products and warehouse storage solutions. Together with our suppliers, employees and customers, we want to effect real and lasting change. For the good of our planet and for the wellbeing of the people around us.”

PALLITE® CEO IAIN HULMES

If you think your business could benefit from switching to PALLITE® products for your distribution or warehousing needs, give our team a call.

FAQ

| 1. What is PALLITE’s material DNA and how does it contribute to sustainable warehouse storage solutions? | PALLITE’s material DNA refers to their lightweight, strong, and recyclable honeycomb board material used in their storage solutions. It contributes to sustainability by reducing material usage, being recyclable, and providing durability for long-term use. |

| 2. What are the key characteristics and benefits of PALLITE’s materials? | PALLITE’s materials are lightweight, yet strong and durable, resistant to moisture and pests, recyclable, and customisable. They offer weight savings, ease of handling, reduced transportation costs, and a sustainable alternative to traditional materials. |

| 3. How does PALLITE’s material DNA compare to traditional materials used in warehouse storage solutions? | PALLITE’s material DNA provides comparable or superior performance to traditional materials like wood or metal, with the added benefit of being lighter, more sustainable, and customisable to fit specific storage requirements. |

| 4. Are there any specific applications or industries where PALLITE’s material DNA is particularly advantageous? | PALLITE’s material DNA is advantageous in various industries, including e-commerce, retail, automotive, pharmaceuticals, and manufacturing, where lightweight, sustainable, and customisable storage solutions are desirable. |

| 5. Can you provide examples of businesses that have implemented PALLITE’s material DNA in their warehouse storage solutions and the outcomes they achieved? | Companies which have adopted PALLITE’s material DNA for their warehouse storage, resulting in reduced costs, increased efficiency, and improved sustainability performance. Check out our Case Studies for more! |